RACING HARNESSES -

what to know before you buy

SUMMARY OF CONTENT

SFI and FIA Harnesses - commonalities and differences

The Webbing

The Security Buckles and Adjustment devices

Pull-up or Pull-down harnesses

3 inch or 2 inch wide belts

4, 5, 6, 7, or 8 Point Harnesses

SFI and FIA Harnesses

FIA tagged racing harnesses and nets have a 5 year lifespan. For SFI harnesses and nets it is 2 years. Both FIA and SFI tags will now state the expiration date. The FIA states the year and the product is good until December 31 of that year.

WHY FIA HARNESSES HAVE A 5 YEAR EXPIRATION DATE

FIA mandates polyester webbing, SFI stills allows nylon.

Nylon thread is stronger but polyester’s finer thread means it can be woven multiple times, which increases the web’s strength.

Nylon has more stretch because it an absorbent material. Polyester is hydrophobic (repels water and dries quicker.)

Nylon does not match Polyester’s longevity. After 2 year UV exposure new Nylon loses 52% of its strength - breaking at 5,069lb. New Polyester loses 23% - breaking at 8,056lb. (SFI’s minimum requirement is 6,300lb.)

Polyester’s elasticity is also superior. Nylon’s elasticity (that is the ability to resume its normal shape after being stretched) drops dramatically after 2 years. For polyester this drop occurs after 5 years.

NOTE - Many SFI manufacturers now do use polyester webbing. However, SFI continues to tag for only 2 years for both safety - and budget considerations. Nylon is cheaper, but more importantly SFI wants to keep all racers safe. Therefore they base their standards on the presumption - that you are racing hard, every weekend, year round in an open cockpit, in all weather conditions - UV exposed. AND that you do not take care of your harnesses.

CHOICES…SFI or FIA

You have choices from multiple manufacturers, but each manufacturer has to pass safety tests quantified from only two sanctioning bodies - the FIA or SFI. The required SFI tests are performed at the appropriate, licensed facilities. FIA racing harness manufacturers build to meet, and even surpass, the latest FIA rules and testing.

https://www.fia.com/sites/default/files/8853-2016_safety_harnesses.pdf

The finished product is then presented to their countries (limited,) FIA sanctioned testing facilities. That countries ASN (motorsport governing body) presents the results to the FIA and handles the approval process.

FIA 8853-2016 is the latest homologation for racing harnesses, and after 2023 all FIA belts will be manufactured to this higher standard. For example, the dynamic testing (sled and impact speed) requires the harness to withstand forces close to 70Gs (from 50+/- 1km/h to 67 +/- 1km/h), from multiple angles. The peak change in velocity will be increased from 32g to 60+g. FIA 8853-2016 there are other new stringent demands to the design including the camlock and adjusters.

SFI 16.1 The harness must not break under 6,300lbs

SF2 16.2 A youth harness (lower) rating

SFI 16.5 The harness must not break under 7,000lbs. Designed for the rigors of off-roading

NOTE: We will always recommend FIA harnesses. They may cost more, but they are stringently tested for strength, longevity, elasticity, degradation, abrasiveness, construction and combustibility. In addition the homologation lasts for five years.

THE WEBBING

Polyester is a manmade filament, derived from oil. It can be manufactured and woven in various configurations to meet the demands/needs of the purchaser. Both The FIA & the SFI have ascribed testing demands that the webbing must surpass, which includes its strength, structural seam strength, and the results from the dynamic tests (sled) after being subject to i) Light-conditioning; ii) Cold-conditioning; iii) Heat-conditioning; iv) Exposure to water; v) Abrasion conditioning. fire-resistance.

For example - FIA - A.7.4 TEST PROCEDURES The specimens shall be tested for combustibility in accordance with ISO3795:1989.

The width of the belts are also homologated. The FIA limits the width to not less than 44mm (1.73”) for the pelvic and crotch straps. Shoulder straps should not be less than70mm (2.76”) with a stated 44mm for shoulder straps that are used with FHR devices.

There are a very limited number of webbing manufacturers that produce a product that meets the SFI & FIA standards. However, brands can specify a higher standard or purchase webbing that has a different weave with different characteristics, and this will affect the price of the harness. For example, the finer the weave, such as those used by Schroth and Sabelt, the smoother the belt moves with the harness adjusters for a more precise and safer fit - but increasing the price of the product.

THE SECURITY BUCKLES AND ADJUSTING DEVICES

Security buckles or more commonly know as camlocks, are individually tested and tested with the harness for strength, conformity, positioning and release properties especially under duress. Similarly for the harness adjusting devices (sliders) with an emphasis on slippage - or lack of it.

Two samples of each belt adjusting device shall be tested for micro-slipping in accordance with the requirements of Article A.3.4.1. The strap slip shall not exceed 25 mm per strap, between the anchorage and the buckle. - FIA

The caliber of the camlock affects the price of the harness. For example, Sabelt’s Endura Platinum Full 2” Harness designed for LMP1 and WRC has a lightweight alloy billet machined (one piece) camlock with a unique funneling system that has been designed for easy clip in and a quick release. However, the price hovers around $2,000.

The adjusters are made from steel, aluminum or an alloy. Steel is more heavy. Aluminum is lightweight and the designs lead to an easier, quicker and smoother adjustment, yet more expensive. To save costs some brands use a mixture of aluminum and steel adjusters on their different models. The steel on the lap belts and the aluminum on the shoulder belts, where an easier and precise adjustment is more critical.

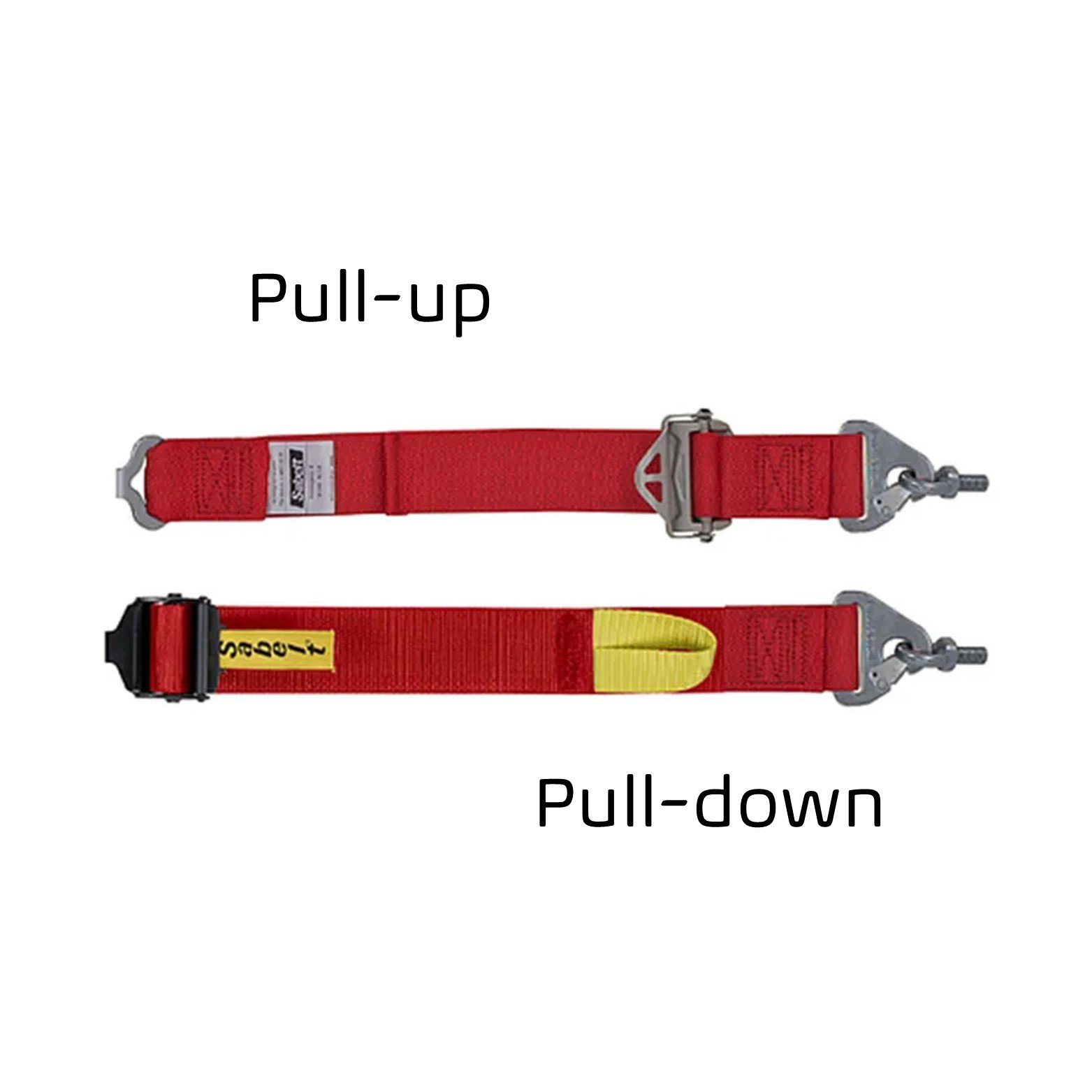

PULL-UP OR PULL-DOWN HARNESSES

Pull-up (PU) or Pull-down (PD) refers to the type of adjustment on the lap belt. Pull-up and the adjuster is placed close to the harness vehicle mounting location. The driver will be pulling the belt up and towards the camlock. The opposite is true for Pull-down.

PD is preferred by endurance teams - quick and easy access.

PD is preferred by drivers with tight cockpits

PU harnesses are more available and generally cost less. For comfort, drivers with larger torsos prefer pull-up harnesses.

Harnesses are usually constructed as PU or PD, but some manufacturers have found ways to offer both options.

Sabelt Enduro Silver – Full 2″ The harness kit includes two sets of lap belts - PU and PD.

Schroth Flexi 2 x 2 Offers a unique design. The lap belts can be changed from a PU configuration to a PD by simply rewrapping the hardware.

Current 3” and 2” webbed belts are strong, and tested to survive almost identical forces. Note - All pro racing FIA harnesses are full 2” belts. The FIA mandates 2” shoulder webbing when used with a FIA compliant Frontal Head Restraint (FHR, HANS.) The tags on the FIA 2” shoulder belts will display it is FHR (frontal head restraint) compliant.

It is now known that the 3” lap belt can do more harm than the 2”. Primarily because it is too wide to fit into the ‘hip pocket’ that is created when a driver sits. The 3” sits on top of the hip bone (the Iliac crest) and in the event of a crash can move upwards resulting in damage to unprotected soft tissue. The 2” belts gets closer to the body. It also allows the driver to fully tightened the belt - for greater hip containment. In addition the 3” lap belt is more inclined to fold, so potentially inflicting greater damage to body by cutting into the body’s soft tissue.

3 INCH OR 2 INCH WIDE BELTS

We do not recommend the use of 4 pt. harnesses in cars, unless they are Schroth Profi ASM (anti-submarining and car specific.) We recognize 4 pt. harnesses are used in Rally Racing and other Off-Road adventures.

5 pt. harnesses can no longer receive a FIA homologation. SFI continues to certify 5 pt. harnesses for track use. In some vehicles, especially formula and older or vintage model, only 5 pt. harnesses can be fitted.

Testing and history has shown the 5th, crotch belt can cause serious injuries in the crotch area for both male and female drivers. In addition, the added 6th belt, along with the 5th belt persuades the driver’s thighs to spread for a more race-appropriate sitting position.

All 6 point harnesses have two lap or hip belts, two shoulder belts and two crotch belts and can receive both a SFI & FIA homologation.

7 point harnesses add a (7th) Negative G strap between the 5th and 6th (anti-submarine) belts and is designed to hold the Camlock in position. These harnesses can be SFI 16.6 rated, but not FIA.

8 point FIA harnesses exist, but not common. They are designed to sandwich the driver’s FHR between the double shoulder belts. The intention is to better contain the the head and neck device while the lower 3” belt offers greater driver comfort